cnc rpm for wood|Free CNC Speed and Feed Calculator and Formula : Baguio Feed rate and RPM: The main variables to determine for CNC operations. Affect tool life, surface finish, and machining time. Cutting speed and chip load: The reference values to calculate feed rate and RPM. Depend on material and tool diameter. Formula and modification: The method to get a starting estimate of feed rate and RPM. Itinutok Ko, Ipinasok Ko Scandal – Butas Wetpaks ni Ate Girl Maganda! HD 57.73K. 100%. EUT sa Campus Challenge – Gagi Ampota Muntik Pa Masita ng Mga Gwardya. HD 89.34K. 100%. Sabay Tayo Maligo Lalabs, Ganito Talaga Diskarte Dapat May Kantot sa Pepe. HD 46.71K. 100%.

cnc rpm for wood,

Here’s your comprehensive guide to Feeds and Speeds for Wood, together with Tips and Techniques that are specific to cutting wood on a CNC Machine. When calculating feeds and speeds for wood, we generally look at 4 different famillies. You can see them in our G-Wizard Feed and Speed Calculator’s Material menu: Just 4 wood types? Why not more?

What is the best cutting speed for wood? With a carbide end mill, typical SFM values for Wood are 1500 SFM. We can use a simple formulat to convert SFM to cutting speed in rpm: Spindle RPM = SFM / Circumference of your End Mill. or. Spindle RPM = SFM / (Tool diameter * Pi) More CNC Wood Cutting Resources. Machining Wood in a Vertical Machining .

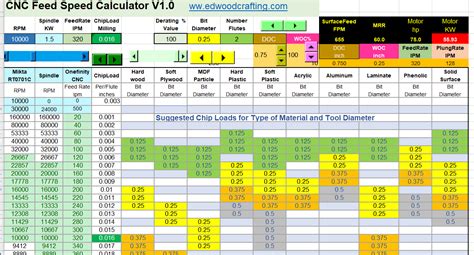

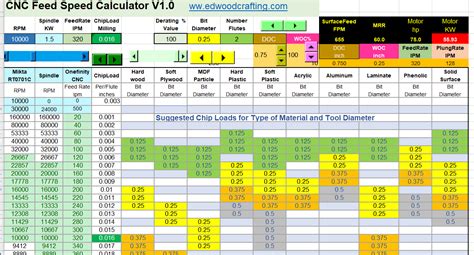

Feed rate and RPM: The main variables to determine for CNC operations. Affect tool life, surface finish, and machining time. Cutting speed and chip load: The reference values to calculate feed rate and RPM. Depend on material and tool diameter. Formula and modification: The method to get a starting estimate of feed rate and RPM.cnc rpm for wood Feed rate and RPM: The main variables to determine for CNC operations. Affect tool life, surface finish, and machining time. Cutting speed and chip load: The reference values to calculate feed rate and RPM. Depend on material and tool diameter. Formula and modification: The method to get a starting estimate of feed rate and RPM. I created a Free CNC calculator to help sort a delicate balance between Feed Rates, Chip Loads, Spindle Speed, and Power that go into finding a CNC setup the optimizes finish quality and minimizes the time required.

Free CNC Speed and Feed Calculator and Formula Free CNC Speed and Feed Calculator allows CNC Machinists and CAD/CAM Programmers to calculate milling and drilling speeds and feeds for a wide variety of materials, and tools types. A feed rate of 100-200 inches per minute (IPM) and a spindle speed of 18,000-24,000 revolutions per minute (RPM) are suitable for general wood cutting applications. Optimizing Feeds and Speeds for CNC Routing Woodcnc rpm for wood Free CNC Speed and Feed Calculator and Formula What speed and feed should you run your bits at. This post should give you a head start. Perfect for CNC beginners, carbide 3d shapeoko, and inventables xcarve users. To learn what is SFM and how to go from SFM to RPM, click this link. Spindle RPM Formula = (12 * SurfaceSpeed) / (PI * CutterDiameter) Number of Flutes (Teeth): ** Feed Rate Formula = Chipload * NumberFlutes * RPM. Milling Surface Speeds for HSS End Mills. Material. Surface Speed (SFM) Aluminum - Wrought (6061) 250. Brass. 200. Cast Iron - Ductile.

cnc rpm for wood|Free CNC Speed and Feed Calculator and Formula

PH0 · Wood Feeds and Speeds Calculator – Calculator

PH1 · What Are the Recommended CNC Feeds and Speeds for Wood?

PH2 · Hardwood Speeds and Feeds Table

PH3 · Free CNC Speeds and Feeds Calculator

PH4 · Free CNC Speed and Feed Calculator and Formula

PH5 · Definitive Guide to Feeds and Speeds for Wood

PH6 · CNC Speed/Feed Calculator – EdwoodCrafting

PH7 · CNC Feeds and Speeds Calculator Wood [Guide + Easy Tips]

PH8 · CNC Feeds And Speeds. A Starting Point.

PH9 · CNC Feeds & Speeds Formula (How to Calculate Feed Rate)